Undercarriage Measurement for Caterpillar and other bulldozers

Undercarriage Life and Wear. A fair estimate of life on a dozer undercarriage is around 4,000 hours. It really depends on the dozer's application on which parts will wear out first. In some cases, sprocket segments will be the first to go. In harder rock conditions, track shoes will be the first thing on the list. Bushing Turn and Wear Measurement

Acco Dozer Undercarriage a photo on Flickriver

Undercarriage can account for as much as 50% of your small dozer's costs, so it pays to invest in a system that delivers the most value for your specific machine and work conditions. Weigh these factors and take advantage of your Cat dealer's analysis tools as you make your selection.

Avoid Damage to your Dozer Undercarriage with Training on Cat

In 2021, Deere implemented on its largest dozer, the 1050K, a suspended double-bogie undercarriage designed to minimize vibrations and shocks during operation, which can accelerate wear and lead.

The Proper Way to Conduct a Dozer Undercarriage Inspection Home

We will have a quote back to you within minutes for the D5C XL Undercarriage! Click to Start a Caterpillar D5C XL Undercarriage Quote OR call 1-800-255-6253. Prices shown are estimates and will vary depending on condition and availability. Huge Undercarriage Inventory. Worldwide Parts Network.

Undercarriage for Dozers Cat Caterpillar

Dozer undercarriage maintenance issues account for an average of 50% of parts and service costs. That makes it extremely important to select the right undercarriage from the start and keep it properly maintained. This video will help you know what to look for during your daily bulldozer maintenance routine.

Undercarriage for Dozers Cat Caterpillar

On new or used D9-D11 dozers, Cat Undercarriage CVAs can help you maximize your undercarriage investment. It starts with controlled cash flow. You pay only for the hours your undercarriage achieves, which can be up to 20% more than the competition. Other flexible options range from replacement kits to dealer labor and managed inventory.

Boss Machinery Caterpillar D6M LGP (FULL NEW UNDERCARRIAGE!)

Caterpillar Maintenance Expert Nick Rummel shares tips and ideas for maintaining your Cat® Dozer Undercarriage. For additional information on Cat Maintenanc.

D8518 the latest Komatsu dozer to get extralonglife PLUS undercarriage

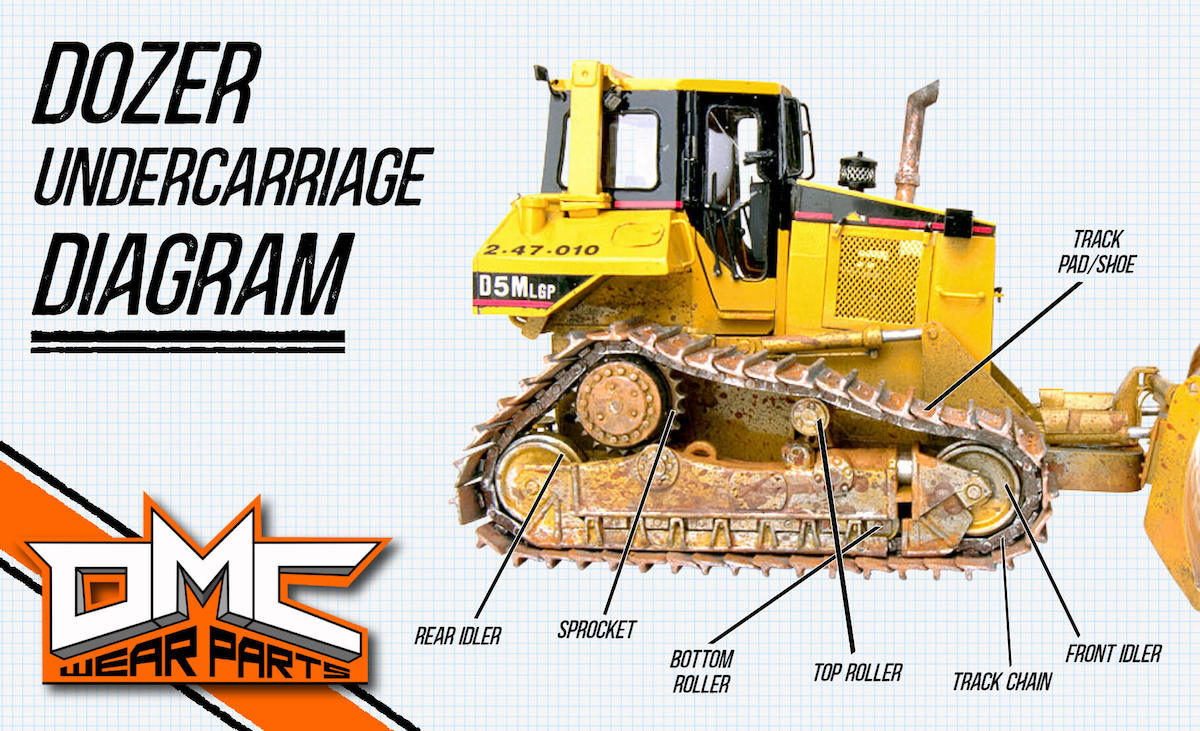

The final drive on a dozer undercarriage is the part responsible for turning the track and propelling the machine forwards and backwards. By converting hydraulic energy into mechanical power the final drive turns the sprocket and in turn, rotates the track. Inside of the final drive, planetary gears transform high speed input into low speed.

.JPG)

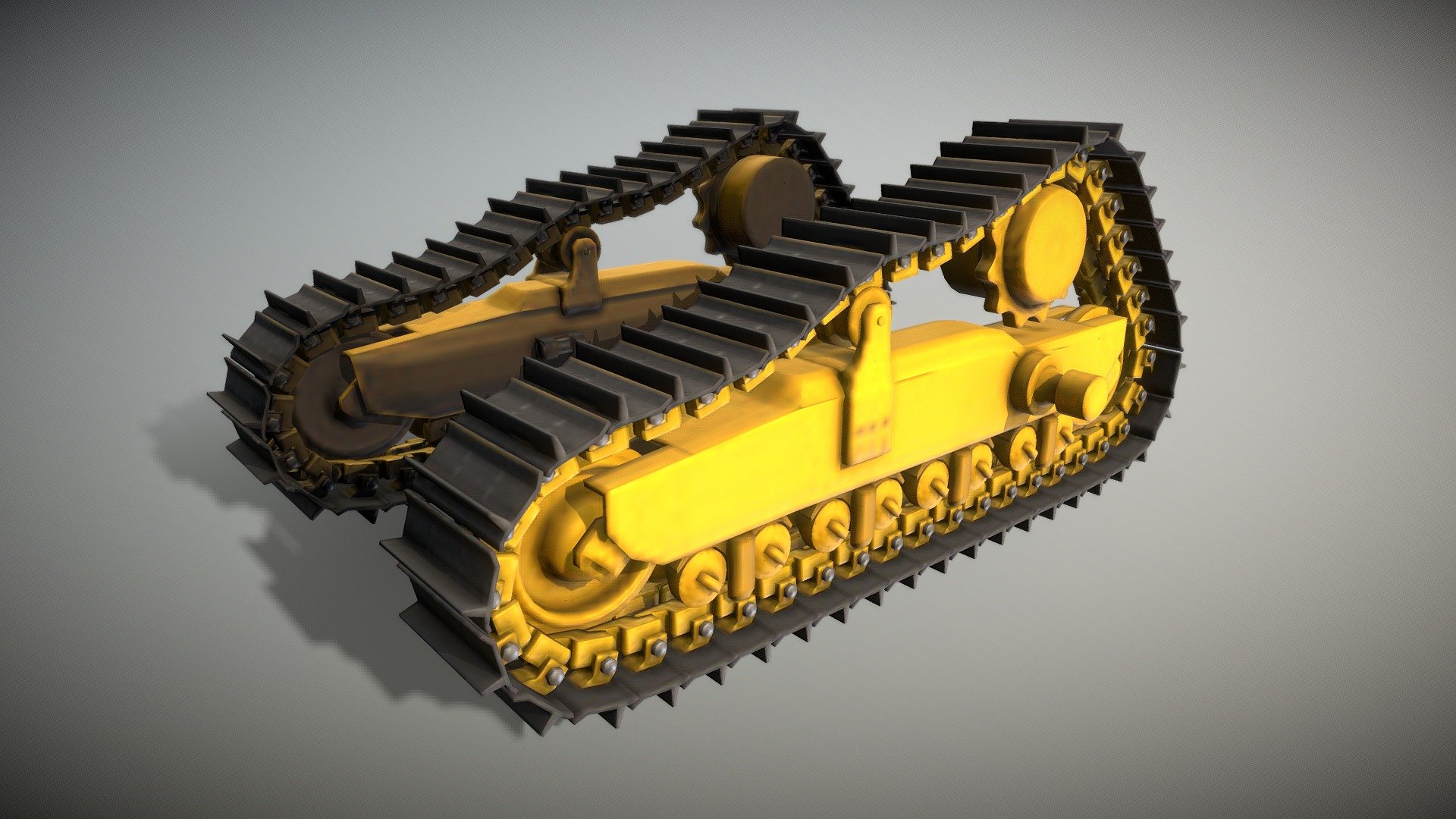

Bulldozer Undercarriage HighPoly Version CGTrader

A bulldozer's undercarriage parts withstand most of the wear and tear of the entire vehicle. This wear and tear can add up and lead to equipment failure and downtime without the proper inspection, maintenance, and repairs. Don't let faulty equipment get in the way of your construction and landscaping jobs. Prevent downtime by inspecting.

RigTest (1) Bulldozer Undercarriage 3D model by VISAll3D (VISAll

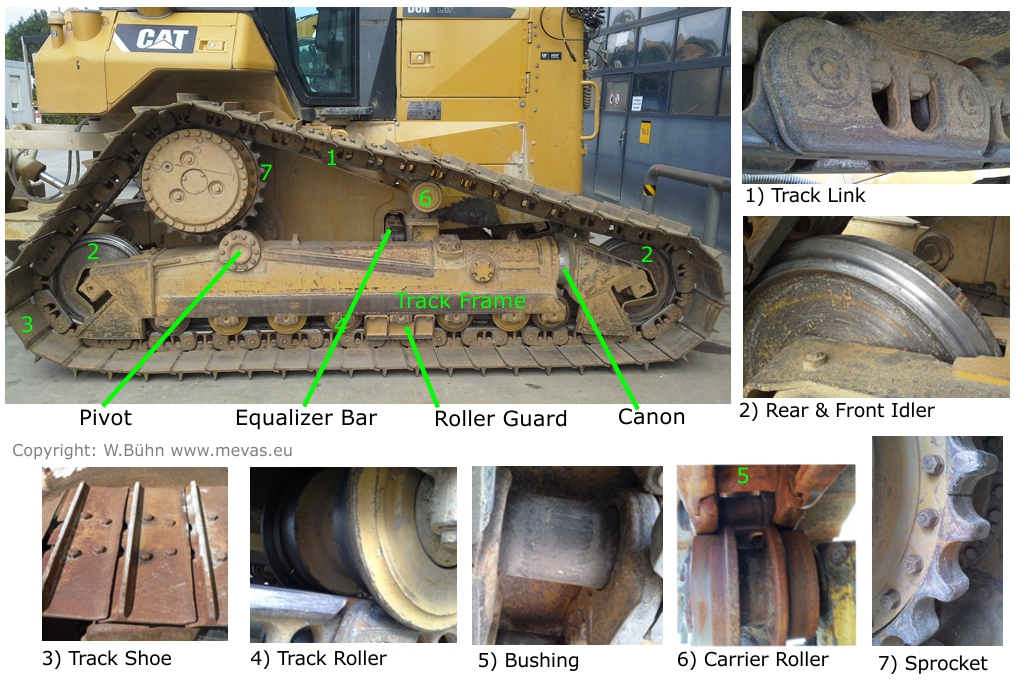

Measure the width of the shoes with a tape measure and the depth of the shoes with a depth gauge. 2. Top roller. Use the caliper tool in the kit to measure the diameter of the top roller. Slide.

How Often Should Undercarriage Be Inspected? TrackTreads Asset Wear

The undercarriage represents on average 50% of your dozer's owning and operating costs. Cat undercarriage components wear at a balanced rate, giving you longer life with predictable downtime and lower repair costs over the life of your bulldozer. Designed based on years of field experience, a Cat general duty undercarriage is recommended for.

Dozer Undercarriage Maintenance Cat Caterpillar

Dozer Undercarriage Inspection, Maintenance, and Repairs. Overlooking undercarriage maintenance is never a good idea. Ignoring good practices when it comes to dozer management and upkeep can create problems that get quite costly. Such as a chain snapping or breaking while on a job site. While issues like these create big problems for operators.

INTERNATIONAL T340 Crawler Dozer Undercarriage

The Undercarriage and the Operator Effect. The undercarriage of a dozer is built on a system of moving components: rollers, idlers, tracks and other parts. What many don't know is that how the machine is operated plays a critical role in the health of the undercarriage. Important operating tips include:

Dozer Undercarriage Parts DMC Wear Parts

All the components in a dozer undercarriage are designed to wear out together at roughly 4,000 hours, or half the service life of the engine. A midlife tune-up typically happens at 2,000 hours.

Case Improves M Series Dozer Undercarriage Pivot Equipment Parts

Bogie Assemblies. ITR America Produces and Distributes through our dealer network, High Quality Undercarriage Track Components for Dozers, Crawler Loaders, Excavators and other Crawler type equipment. Undercarriage Parts include Track Chains, Rollers, Idlers, Track Pads, Track Hardware, Sprocket Segments, Sprockets, Track Adjusters and more.

CAT D8R Dozer Undercarriage Changeout by WestTrak YouTube

THE RIGHT UNDERCARRIAGE TO DO THE WORK BY CHOOSING A CAT® UNDERCARRIAGE, YOU ARE SETTING YOURSELF UP FOR SUCCESS. Every Cat® Undercarriage is built to wear as a system, to optimize the overall performance of your Cat dozer. GENERAL DUTY (GD) HEAVY DUTY (HD) HEAVY DUTY XL (HDXL) CAT® ABRASIONTM WHERE IT SHOULD WORK General, light-duty.