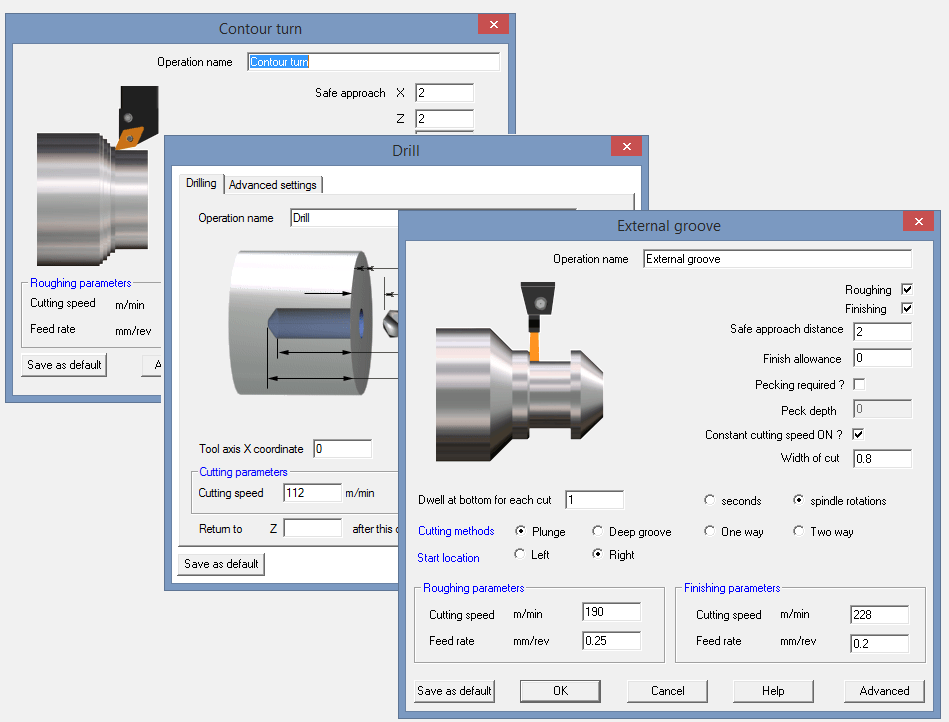

CNC lathe programming software Cadem

Viceroy Lathe. WEIHONG. WinCNC. XYZ Machine Tools. YASDA. Yaskawa. Read & Download CNC Machine Manuals without Limits on any device. Your best companion in cnc machine shop. CNC programming operating manuals and many more.

CNC Machining Handbook Building, Programming, and Implementation by

R epetitive cycles are used in CNC Lathe Programming to minimise the amount of code that has to be written and give us more control over complex shapes and operations. The control system will understand the operation and perform the repetitive cycle following the commands that are given by the programmer until the feature is complete.

Basic Cnc Turning Program Pdf CNC Turning News

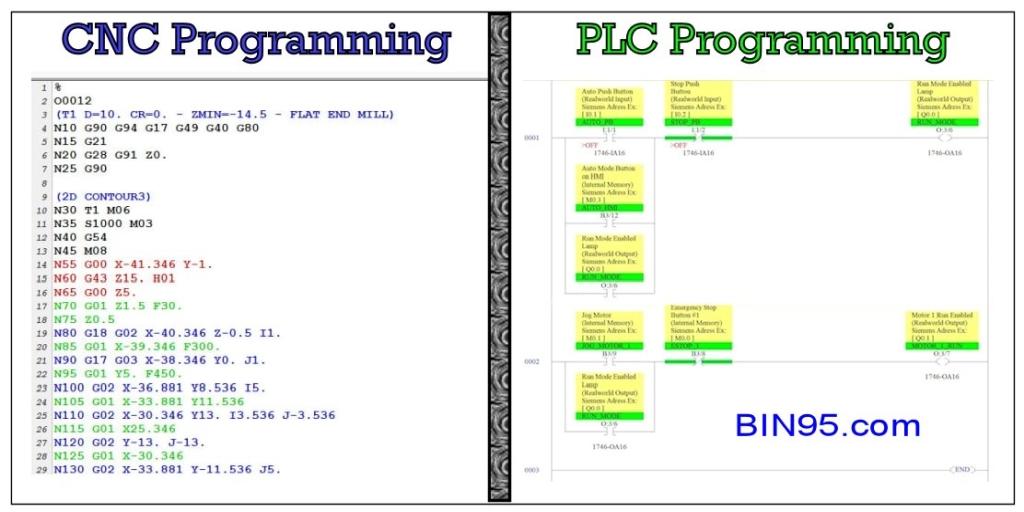

A typical CNC program has (3) parts: 1) Preparation: This portion of the program selects the work and tool offsets, selects the cutting tool, turns on the coolant, sets spindle speed, and selects absolute or incremental positioning for axis motion.

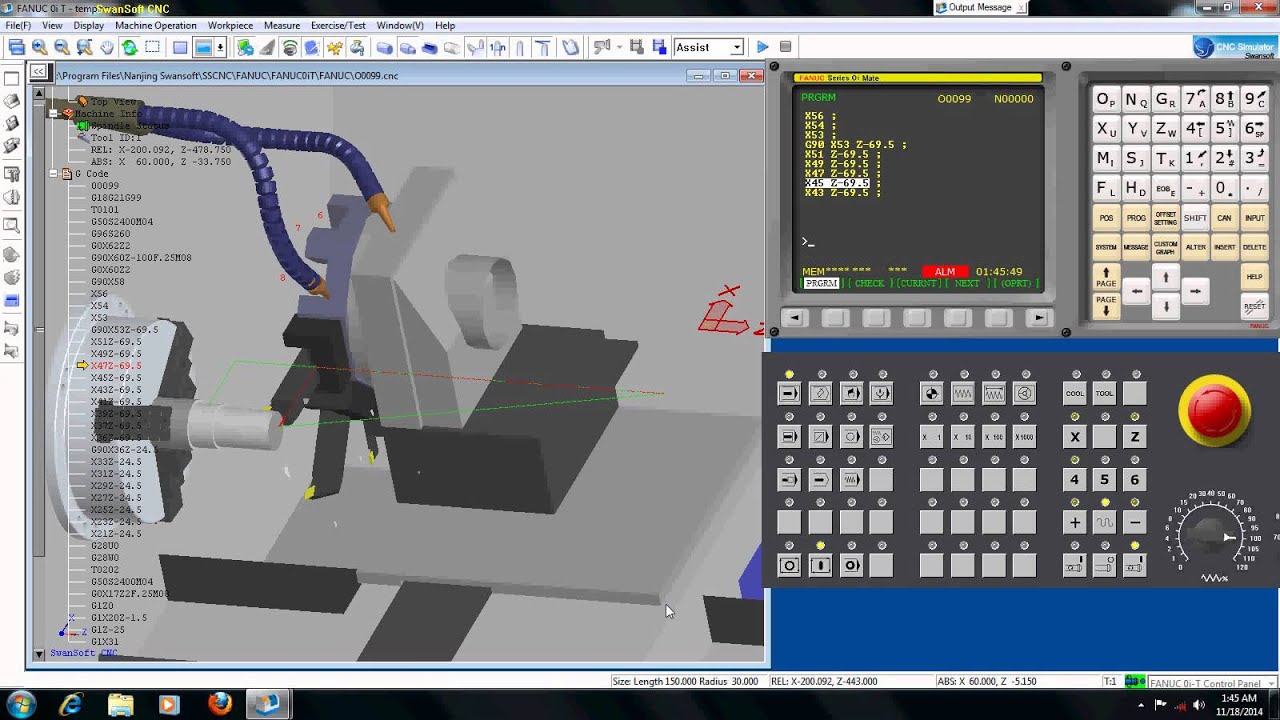

How To Program Fanuc Cnc Lathe

This file is the Adobe Acrobat version of Denford G and M Programming for CNC Lathes. File Optimisation: On-screen display and printing. Graphics: resampled to 600 dpi. Lan guage: European English. Paper size: A4 (210mm x 297mm). Denford Customer Services. Tel: +44 (0) 1484 722733 e-mail: customer_services @denford.co.uk

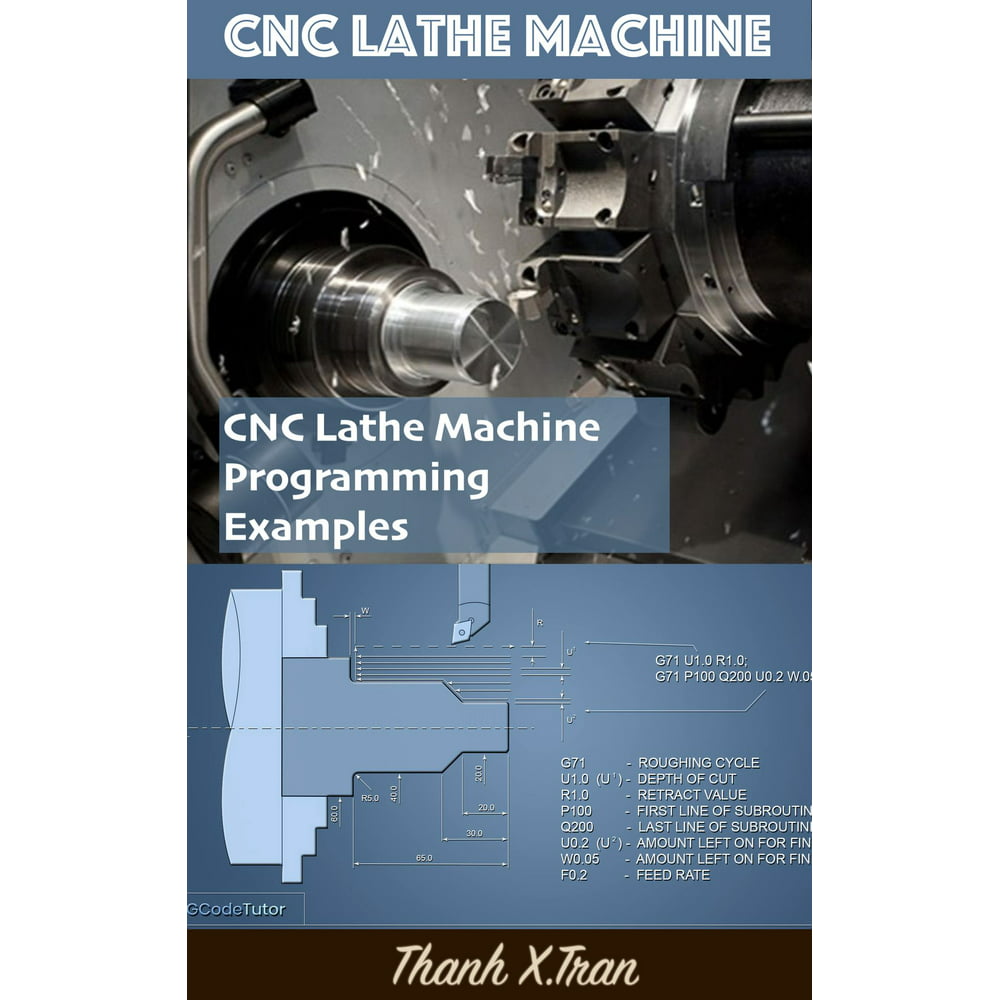

Guide to CNC Lathe Machine CNC Lathe Machine Programming Examples

Chapter 1 The basic knowledge for programming This chapter discusses the terms and commands you should know before learning CNC programming. 1.1 Configuration of the machine tool (CNC Lathe) 1.2 The axes of CNC Lathe 1.3 Format of machining program

Programming the G71 Roughing Cycle on a CNC Lathe Practical Machinist

This paper mainly studies how the importance of programming in CNC lathes and how to use improved programming procedures to improve the machining accuracy of CNC lathes. Discover the.

Cnc Lathe Programming Pdf bouldercrack

Computer Numerical Control (CNC) mills and lathes.. using this course have been taught to set up, program, and operate a CNC mill in less than 24 hours of combined classroom/lab time ; including instruction in HSMWorks.. CNC Machine . Lesson 1 Fundamentals of CNC Machining %

CNC Programming Intro for Beginners (Examples!) MellowPine

the HAAS C.N.C. Lathe. In a "CNC" (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability. The same principles used in operating a manual machine are used in programming a CNC.

Basics of CNC Programming

CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes, and 3D printers. These CNC machines receive their instructions using a programming language called g-code.

Cnc Programming

The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements, which are also defined according to DIN 66025. 2. Work preparation

Cnc Programming

2-1-1 Program Reference Point and Coordinate Values For a CNC lathe, coordinate axes X and Z are set on the machine and their intersecting point is called a "program reference point". The X axis assumes a spindle center line to be a position of "XO", and the Z axis assumes a workpiece finish end face on the tail stock

PDF Fanuc Cnc Lathe Programming Software softdownloadraptecul

Here's what we have for CNC Programming PDF's: CNC Machine Programming Course / PDF eBook Includes examples, Fanuc dialect, and more. Learn to read and write g-code in this 16 chapter tutorial course and eBook. [ Download PDF ] Download PDF DFMA Course / PDF eBook

Example of a CNC Gcode program with explanations of each code block

Computer Numeric Control (CNC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium (computer command module, usually located on the device) as opposed to controlled manually by hand wheels or levers, or mechanically automated by cams alone.

What Is CNC Programming? Unity Manufacture

CNC Lathe Programming for Turning CNCCookbook's G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes CNC Lathes come in a variety of configurations, but for the basics, we'll stick to the simplest and most common setup-2 axes.

CNC Programming Workbook Mill & Lathe CamInstructor

200 Madison Avenue, New York, NY 10016 CONTENTS Preface The term numerical control is a widely accepted and commonly used term in the machine tool industry. Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols.

CNC Lathe Instruction Manual Programming PDF Free Download Free

Take the lathe machine as an example, how to make CNC turning program? Here we bring some CNC lathe programming tips and examples. Related Read: Introduction to G-Code and M-Code CNC Lathe Program Examples Check out the following two simple CNC lathe programming examples of different instructions.