Project Value Stream Mapping MudaMasters

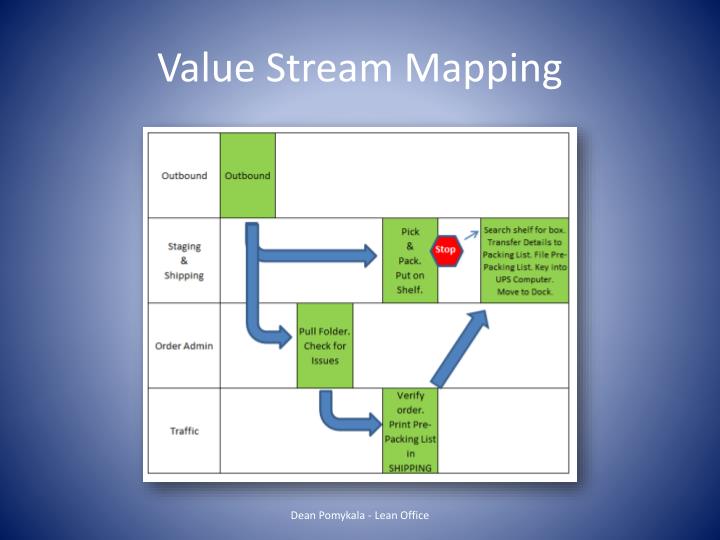

Value Stream Mapping for the lean office is a tool that uses a flow diagram to document in great detail every step of a manufacturing process. This graphical representation of a process is a powerful tool that helps in the diagnosis of process efficiency and allows companies to develop improved processes. Many lean practitioners use Value.

Lean VALUE STREAM MAPPING Cucini Lo specialista del cassone ribaltabile

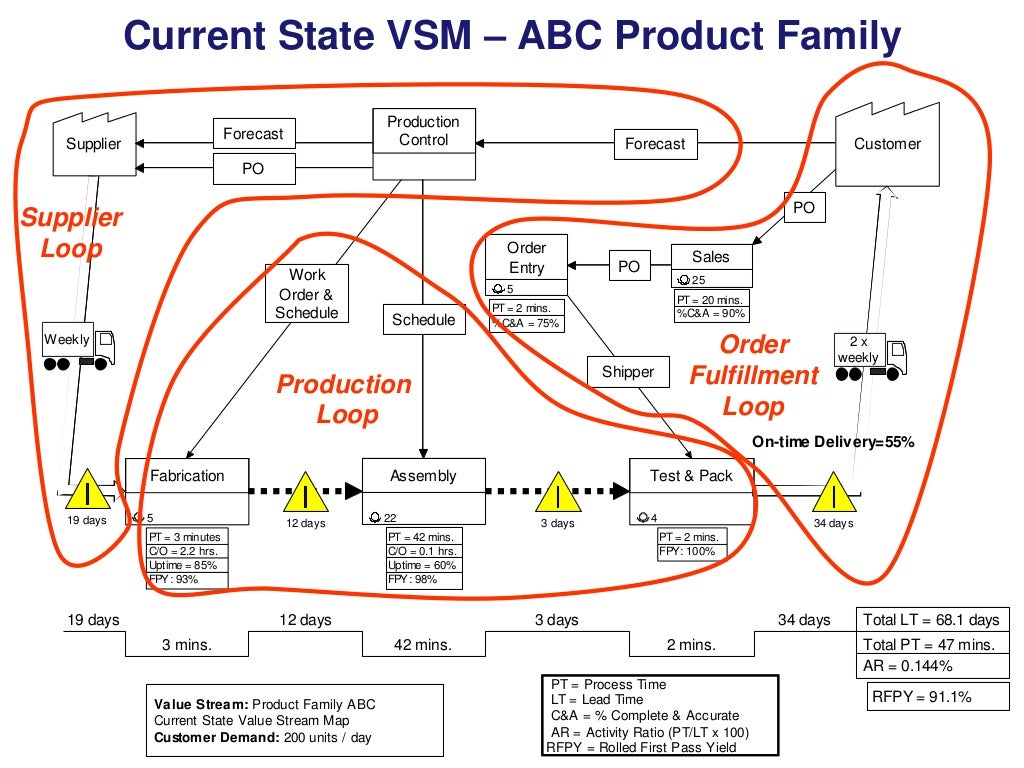

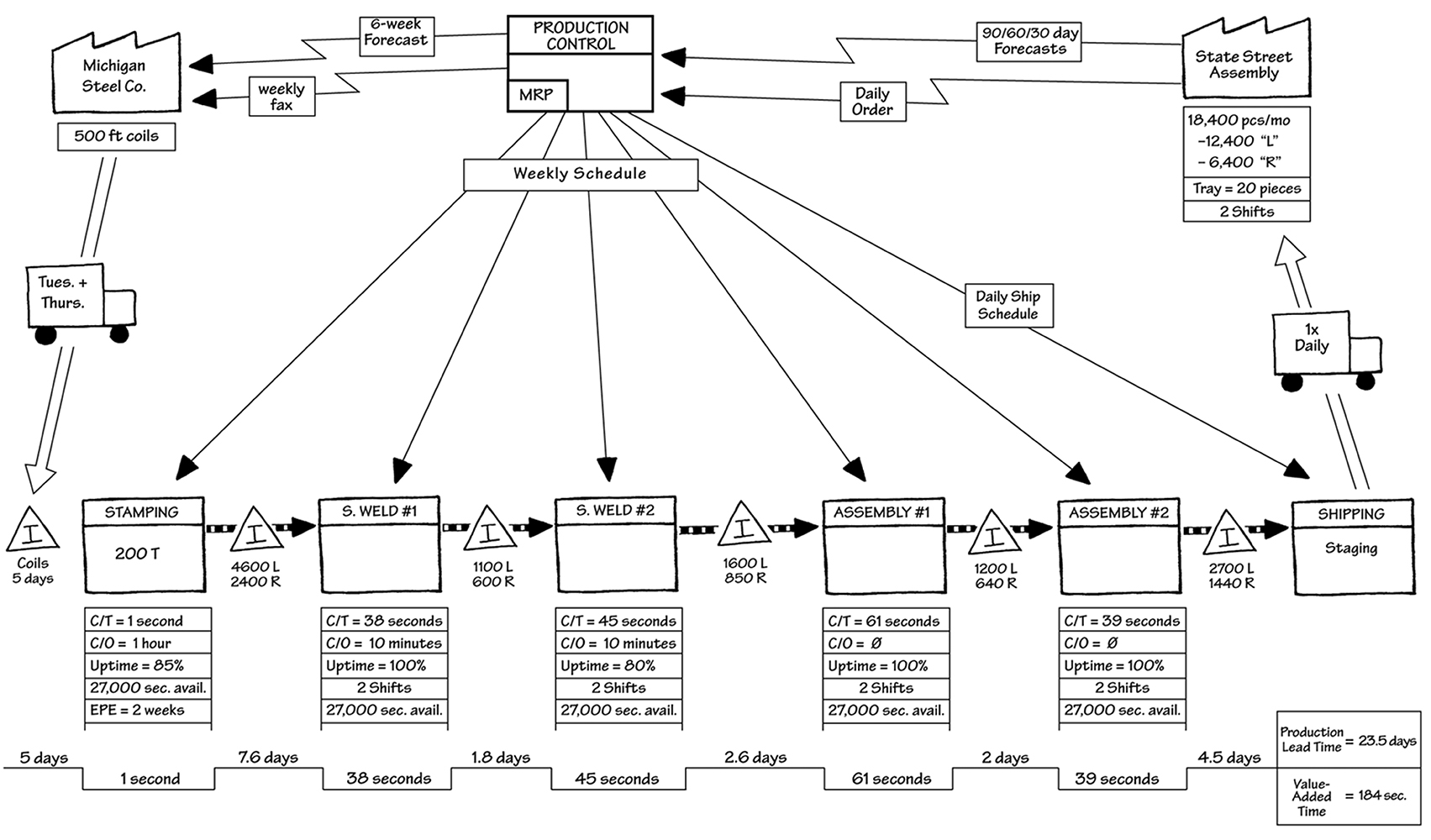

It is important to note that effective value stream mapping is a team effort. Aim to have three to 10 people working on your value stream map to ensure your process improvement is thorough. Value stream mapping is one of the principles of a management practice called Lean. Lean originated with the creation of the Toyota Production System in the.

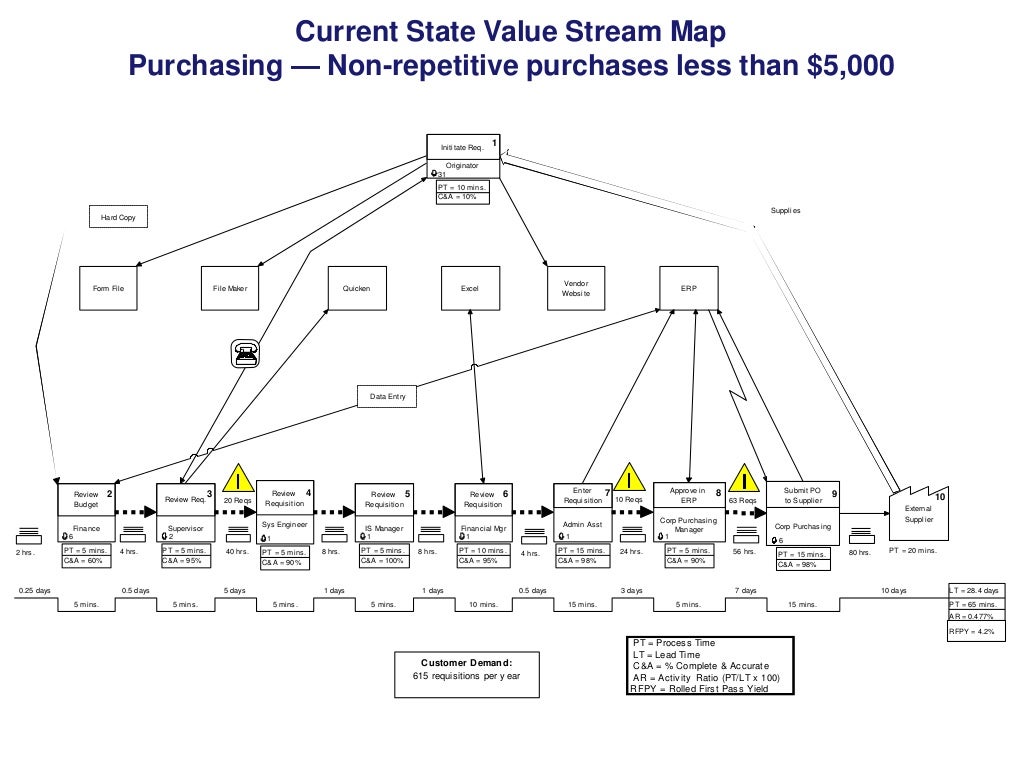

PPT Value Stream Mapping for Office, Service and Healthcare

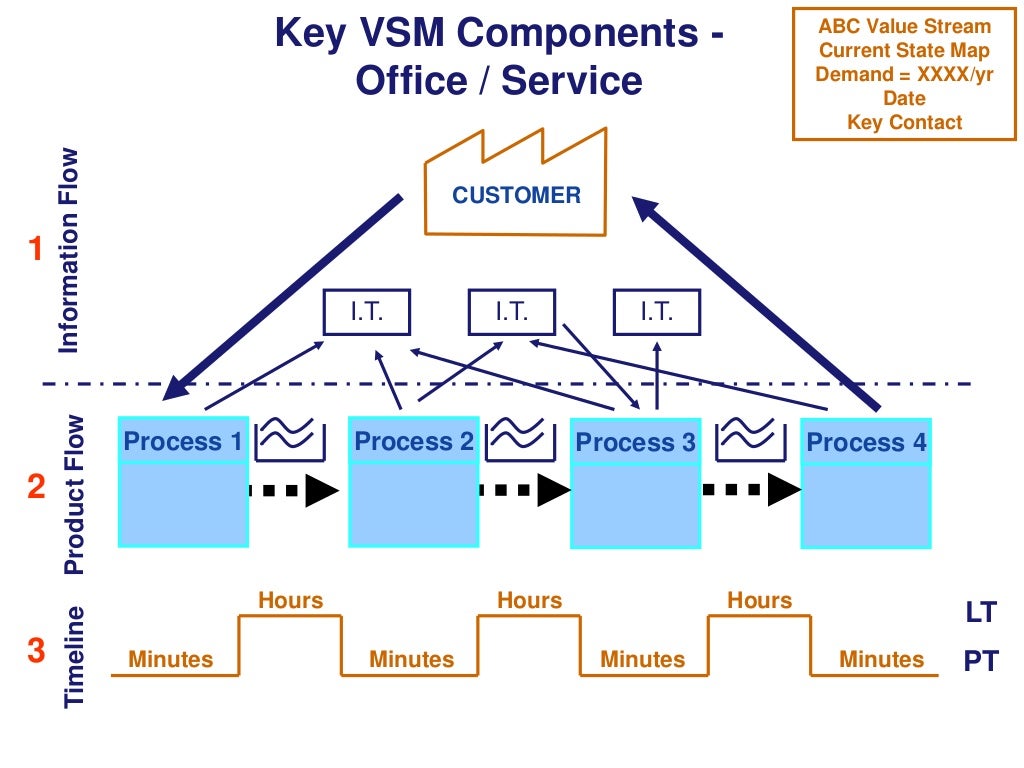

What is VSM? The ITIL ® 4 Foundation publication defines a value stream as a series of steps an organization undertakes to create and deliver products and services to consumers. Value stream maps are also one of the tools from Lean manufacturing.

Value Stream Mapping in Office & Service Setttings

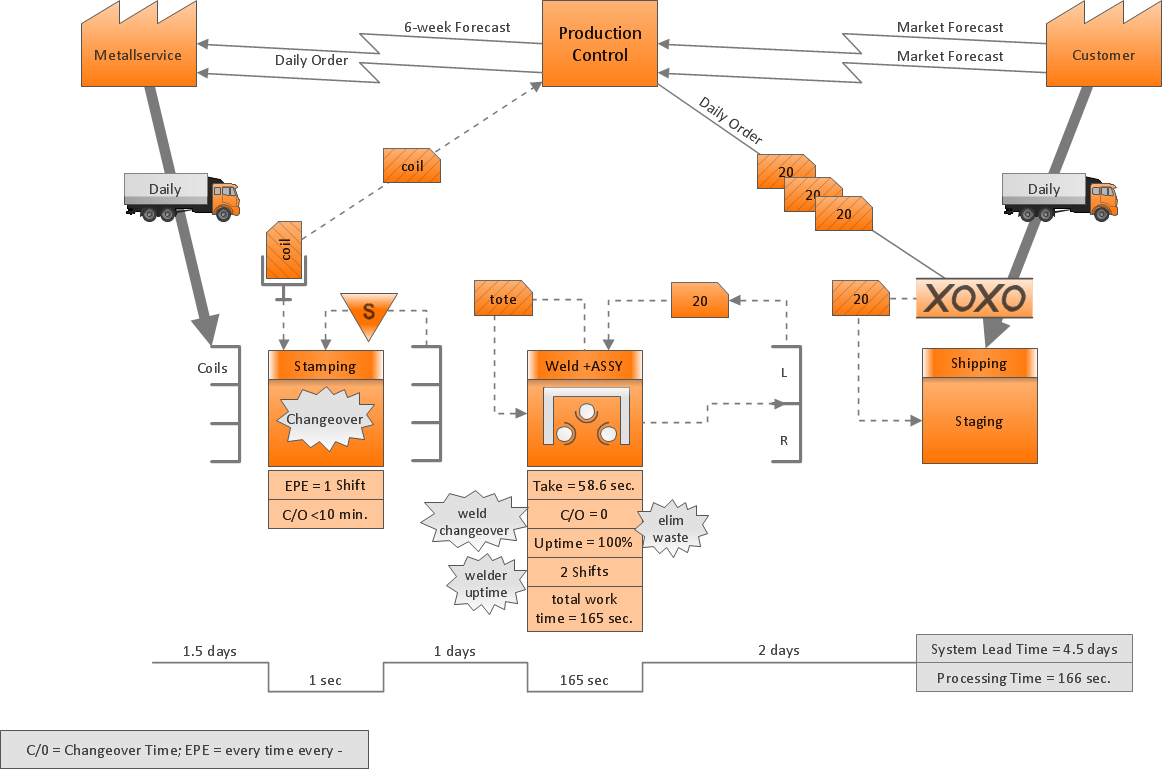

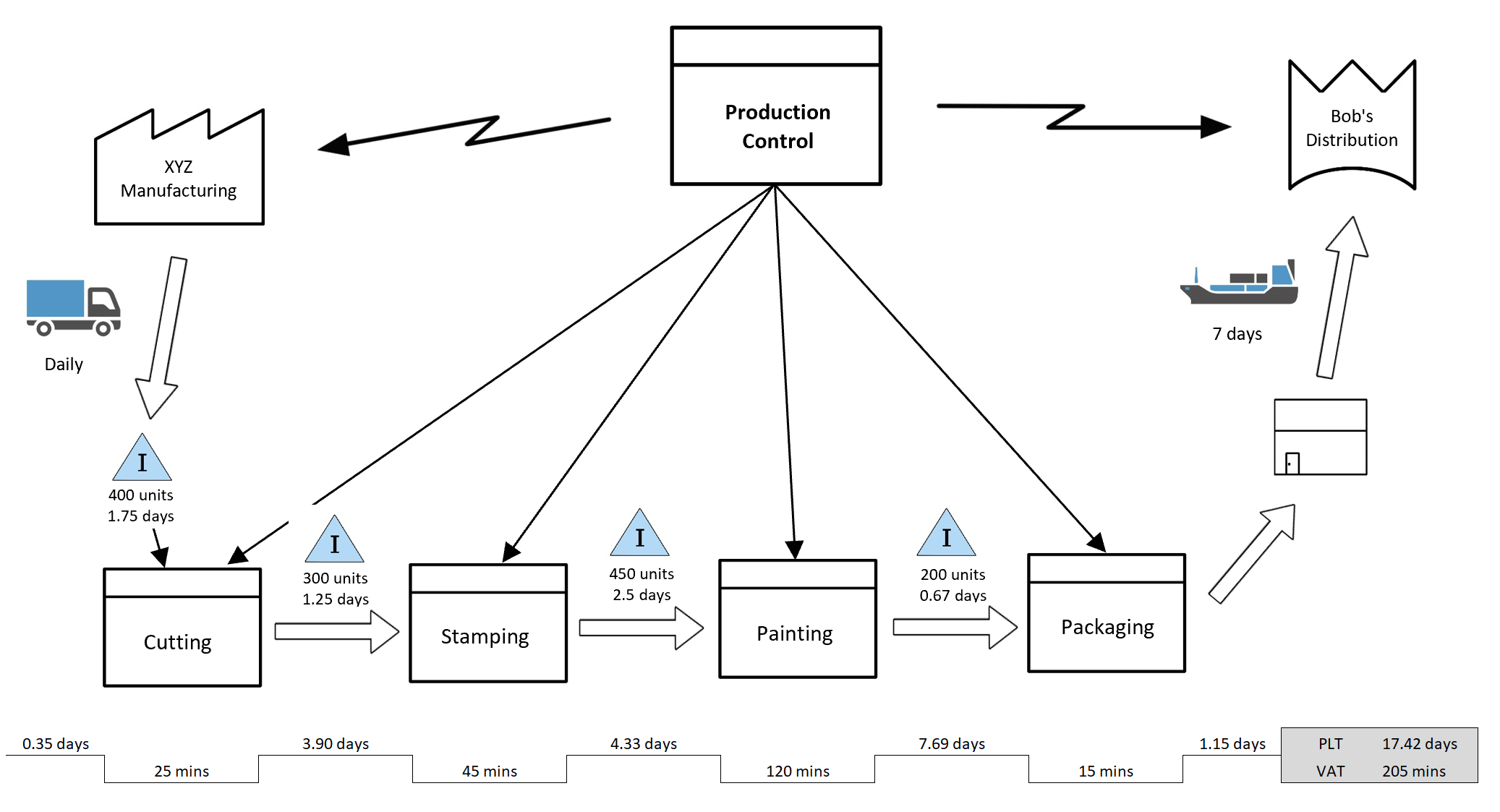

Value Stream Mapping is a Lean tool that is used to visualize a production process. It helps to increase the value of the product or service by identifying bottlenecks and eliminating waste. In this value stream mapping tutorial, you will learn The Origin of Value Stream Mapping What is Value Stream Mapping Types of Value Stream Maps

Value Stream Mapping Template Photos Cantik

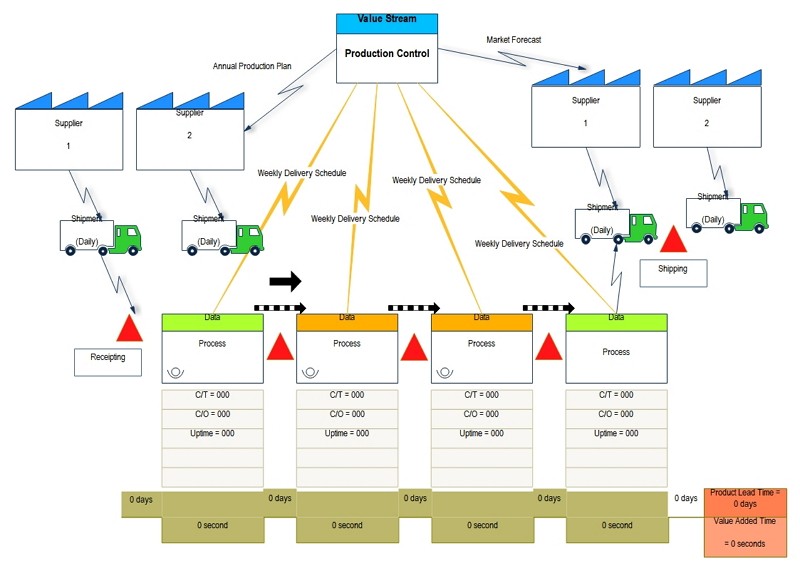

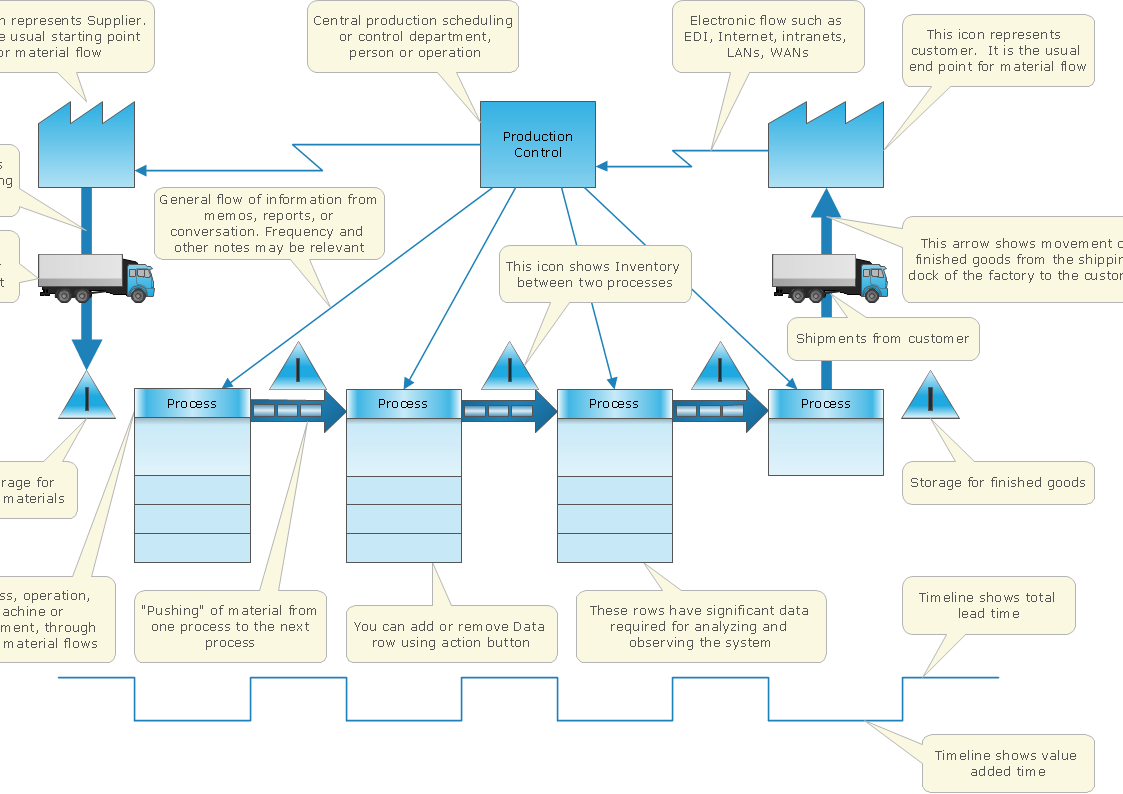

Click File > New. Type value stream map in the Search box, click the Start Searching button, and then double-click Value Stream Map when it appears. From the Value Stream Map Shapes stencil, drag shapes onto the page to represent your processes, information, and materials.

Pic Of Lean Value Stream Map Sexiz Pix

Value stream mapping, also known as value stream analysis or lean process mapping, is a tool used to implement process improvement by identifying waste and reducing process cycle times. VSM is one of the most important tools for Lean Six Sigma (LSS), a leading process optimization approach.

Value Stream Mapping in Office & Service Setttings

Step 1: Understand the Value Step 2: What is our Focus? Step 3: Go to Gemba (Walk the Process) Step 4: Work Backwards Step 5: Define the Basic Value Stream Step 6: Fill in Queue Times Step 7: Fill in Process Data Step 8: Include Smiley Faces Step 9: Include the Value-Added Percentage (%VA) Step 10: Interpret the Value Stream Map (VSM)

Value Stream Mapping in Office & Service Setttings

Click File > New. Type value stream map in the Search box, click the Start Searching button, and then double-click Value Stream Map when it appears. From the Value Stream Map Shapes stencil, drag shapes onto the page to represent your processes, information, and materials.

Value Stream Mapping in Office and Service

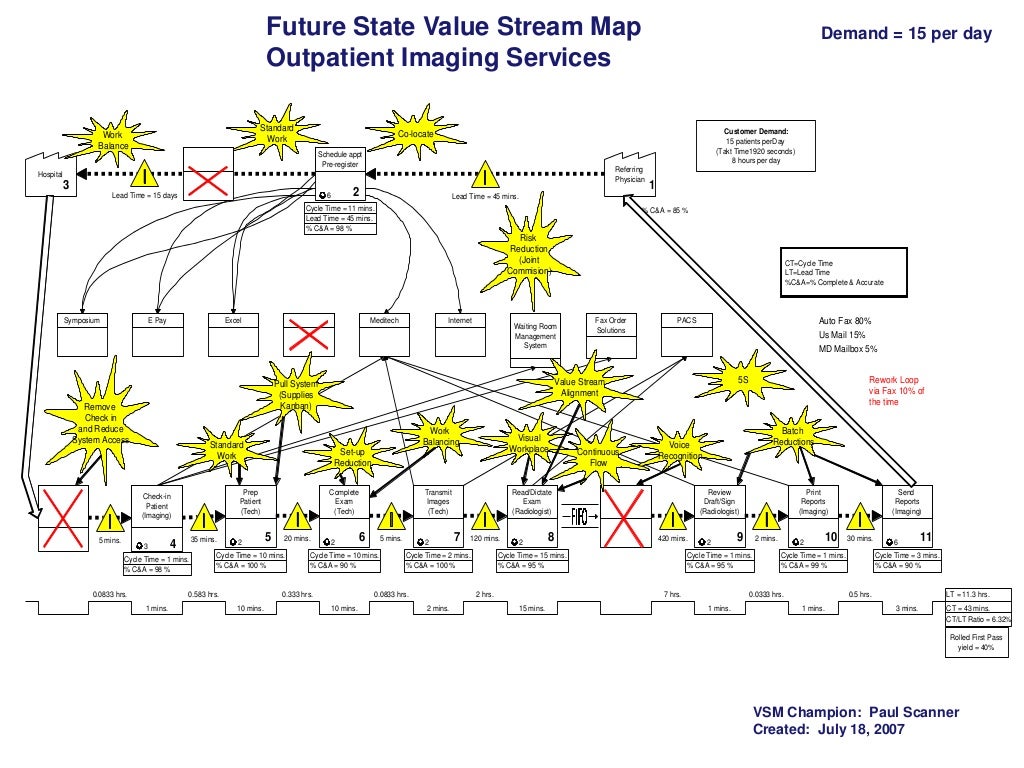

The concept of the 'value stream' comes from the LEAN management approach. Value stream mapping analyses what is currently happening (the current state) and goes on to design a future state for the process focusing on how value is created and delivered to the patient. Value stream mapping can be a particularly effective approach when.

Value Stream Map Kaufman Global Lean And Operational Excellence Riset

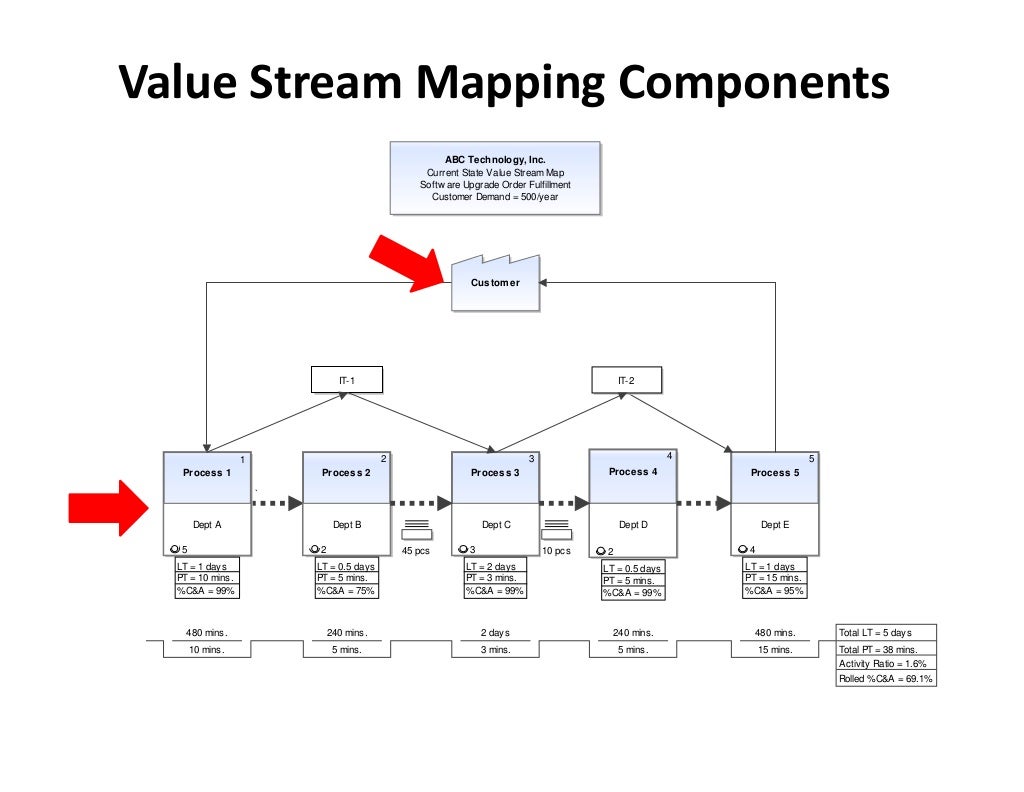

Value stream mapping (VSM) is defined as a lean tool that employs a flowchart documenting every step in the process. Many lean practitioners see VSM as a fundamental tool to identify waste, reduce process cycle times, and implement process improvement.

Value Stream Mapping in Office & Service Setttings

Value stream mapping (VSM) is a powerful tool that is used to optimize processes and increase efficiency across various industries. In this comprehensive guide, we'll dive into the ins and outs of VSM, including its history, benefits for product managers and examples of successful implementations.

Value Stream Mapping in Office & Service Setttings

Value stream mapping (sometimes called VSM) is a lean manufacturing technique to analyze, design, and manage the flow of materials and information required to bring a product to a customer. Also known as "material and information-flow mapping", it uses a system of standard symbols to depict various work streams and information flows.

Value Stream Mapping for the Lean Office Value Stream Mapping Software

Definition, Working, and Examples. Value stream mapping (VSM) shows the events leading up to product usage to map inputs vs. outputs and reduces waste. Chiradeep BasuMallick Technical Writer. September 20, 2022. Value stream mapping (VSM) is a project workflow visualization tool that pictorially represents the events that lead to the user.

PPT Lean Office PowerPoint Presentation ID1653918

Value-stream mapping (VSM) is a fundamental lean practice that involves diagraming a value stream, which includes all the actions (value-creating and nonvalue-creating) needed to move a product or service from raw material to the arms of the customer, including the material and information flow.

How to Implement Kaizen

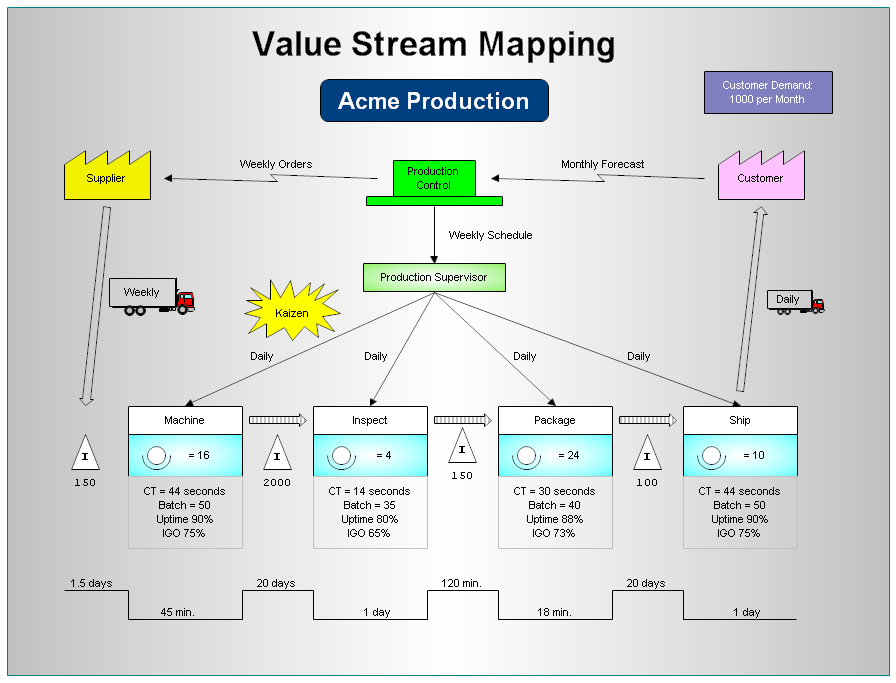

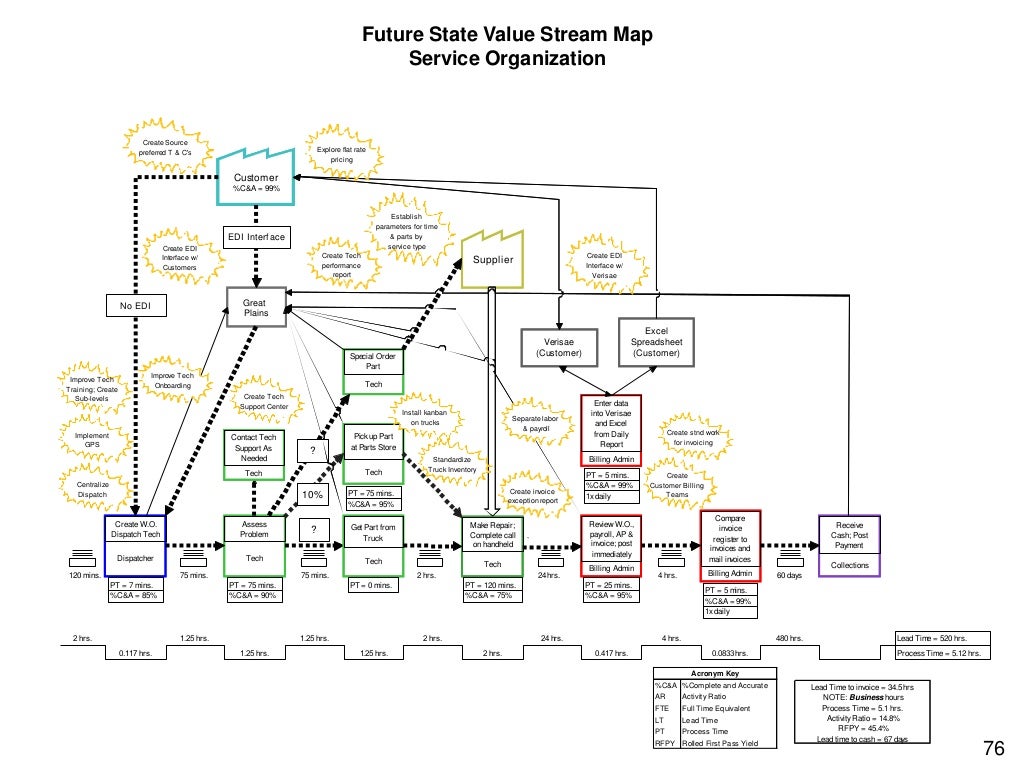

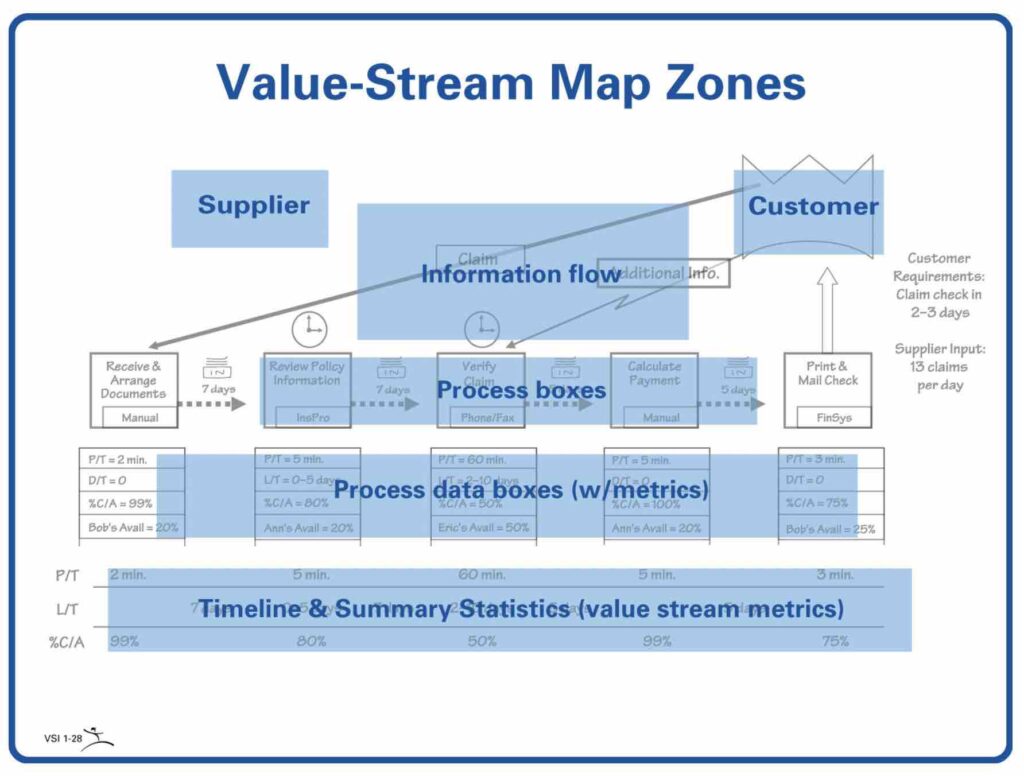

A Value Stream Map (VSM) visually displays the flow of steps, delays and information required to deliver a product or service to the customer. Value Stream Mapping allows analysis of the Current State Map in terms of identifying barriers to flow and waste, calculating Total Lead Time and Process Time and understanding Work-In-Process, Changeover Time, and Percent Complete & Accurate for each step.

Value Stream Map Kaufman Global Lean and Operational Excellence

1. June, 2004 Beau Keyte, Branson, Inc. Value Stream Mapping inValue Stream Mapping in the Officethe Office Lean Service Summit. 2. Course AgendaCourse Agenda 1. Introduction 2. Value Stream Focus 3. The Current State Map 4. The Future State Map 5. Planning Your Changes.